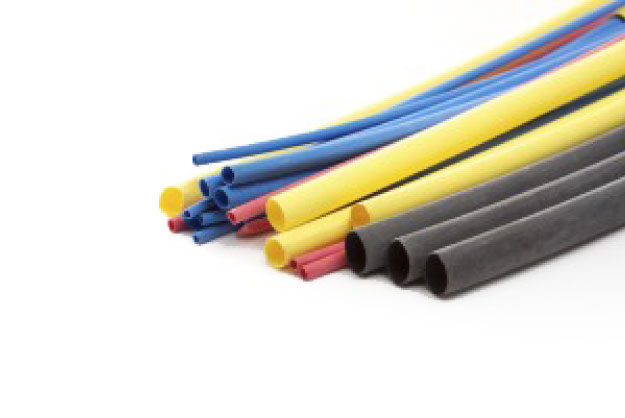

Heat Shrinkable Tube

HAMBURG H-2

Application

HAMBURG H-2 is halogen free, environmentally friendly, flexible, flame-retardant, irradiated crosslinking heat-shrinkable modified polyolefin tubing. It contains no added halogens, and is free of PCBs, PCBs, polybrominated biphenyls (PBBs), polybrominated biphenyl oxides and others (PBBOs, PBBEs and PBDEs) and toxic heavy metal (Pb, Cd, Hg, Cr6+) compounds, which are classified as environmentally hazardous substances. This high-reliability product is widely used for insulation or jacketing of wire harness, strain relief of wire terminations and connections, bundling of wire harness, protection of soldered points, insulation and capsule of electronic components, anti-corrosive protection, identification and color coding, etc.

Feature/Benefits

- Shrink ration:2:1

- Low shrink temperature

- Very flexible, flame-retardant

- Good thermal stability

- Excellent physical, chemical and electrical properties

- No added halogens, free of PCBs, PCBs, polybrominated biphenyls (PBBs), polybrominated biphenyl oxides and others (PBBOs, PBBEs, and PBDEs) and toxic heavy metal (Pb, Cd, Hg, Cr6+) compounds, which are classified as environmentally hazardous substances, Conforms to European RoHS environmental directive.

- Wide range of sizes and colors

Operation Temperature

- Temperature range: -55℃~125℃

- Shrinking temperature: 75℃

- Full recovery temperature: 125℃

- Longitudinal shrinking: 0 ± 5%

Standards/Approvals

- UL224 E255394 125℃ 600V VW-1

- cUL224 E255394 125℃ 600V VW-1

- CSA C22.2 238014 125℃ 600V VW-1

Suface / Print

HAMBURG-A H-2 125℃

E255394 VW-1 CSA -F- (Ф)

Specification values

| Property | Unit | Test method | Standard | |

|---|---|---|---|---|

| Physical | Tensile strength | Mpa | GB/T1040 | ≧10.4 |

| Elongation | % | GB/T1040 | ≧200 | |

| Tensile strength after aging | Mpa | UL224 158℃x168hr |

≧7.3 | |

| Elongation after aging | % | UL224 158℃x168hr |

≧100 | |

| Heat Resistance | - | UL224 250℃x4hr |

No viscidity, No cracking | |

| Cold blend | - | UL224 -30℃x4hr |

No cracking | |

| Electrical | Dielectric strength | KV/mm | GB/T1408 | ≧15 |

| Dielectric withstand | V | UL224 | No breaking for 2500v | |

| Volume resistance | Ω.cm | GB/T1410 | ≧1x1014 | |

| Chemical | Anti Corrosin | - | UL224 158℃x168hr |

Pass |

| Copper stability | - | UL224 158℃x168hr |

Pass | |

| Flammability | - | UL224 | VW-1 | |

Product size

| Size(mm) | (mm) As supplied |

(mm) After recovery |

Packing (M/Spool) |

Application (mm) |

||

|---|---|---|---|---|---|---|

| (I.D.) Inside diameter |

(W.T.) Wall Thickness |

(I.D.) Inside diameter |

(W.T.) Wall Thickness |

|||

| Φ0.6 | 0.9 ± 0.2 | 0.15 ± 0.05 | ≤0.40 | 0.22 ± 0.10 | 400 | 0.5~0.7 |

| Φ1.0 | 1.5 ± 0.2 | 0.15 ± 0.05 | ≤0.65 | 0.28 ± 0.10 | 400 | 0.75~0.9 |

| Φ1.5 | 2.0 ± 0.2 | 0.18 ± 0.05 | ≤0.90 | 0.32 ± 0.10 | 400 | 0.95~1.4 |

| Φ2.0 | 2.5 ± 0.2 | 0.18 ± 0.05 | ≤1.00 | 0.35 ± 0.10 | 400 | 1.1~1.8 |

| Φ2.5 | 3.0 ± 0.2 | 0.18 ± 0.05 | ≤1.30 | 0.38 ± 0.10 | 400 | 1.35~2.3 |

| Φ3.0 | 3.5 ± 0.2 | 0.18 ± 0.05 | ≤1.50 | 0.40 ± 0.10 | 400 | 1.6~2.7 |

| Φ3.5 | 4.0 ± 0.2 | 0.22 ± 0.05 | ≤1.80 | 0.42 ± 0.10 | 400 | 1.85~3.2 |

| Φ4.0 | 4.5 ± 0.2 | 0.25 ± 0.05 | ≤2.00 | 0.45 ± 0.10 | 400 | 2.1~3.6 |

| Φ4.5 | 5.0 ± 0.2 | 0.25 ± 0.05 | ≤2.30 | 0.50 ± 0.10 | 200 | 2.35~4.0 |

| Φ5.0 | 5.5 ± 0.2 | 0.25 ± 0.05 | ≤2.50 | 0.55 ± 0.10 | 200 | 2.6~4.5 |

| Φ6.0 | 6.5 ± 0.2 | 0.28 ± 0.05 | ≤3.00 | 0.55 ± 0.10 | 200 | 3.1~5.1 |

| Φ7.0 | 7.5 ± 0.3 | 0.28 ± 0.05 | ≤3.50 | 0.55 ± 0.10 | 100 | 3.7~6.3 |

| Φ8.0 | 8.5 ± 0.3 | 0.28 ± 0.05 | ≤4.00 | 0.60 ± 0.10 | 100 | 4.2~7.2 |

| Φ9.0 | 9.5 ± 0.3 | 0.3 ± 0.08 | ≤4.50 | 0.60 ± 0.10 | 100 | 4.7~8.0 |

| Φ10.0 | 10.5 ± 0.3 | 0.30 ± 0.08 | ≤5.00 | 0.60 ± 0.10 | 100 | 5.2~9.0 |

| Φ11.0 | 11.5 ± 0.3 | 0.3 ± 0.08 | ≤5.50 | 0.60 ± 0.10 | 100 | 5.7~10.0 |

| Φ12.0 | 12.5 ± 0.3 | 0.30 ± 0.08 | ≤6.00 | 0.60 ± 0.10 | 100 | 6.2~11.0 |

| Φ13.0 | 13.5 ± 0.3 | 0.35 ± 0.10 | ≤6.50 | 0.65 ± 0.10 | 100 | 6.7~12.0 |

| Φ14.0 | 14.5 ± 0.3 | 0.35 ± 0.10 | ≤7.00 | 0.65 ± 0.10 | 100 | 7.3~13.0 |

| Φ15.0 | 15.5 ± 0.4 | 0.40 ± 0.12 | ≤7.50 | 0.70 ± 0.10 | 100 | 7.8~14.0 |

| Φ16.0 | 16.5 ± 0.4 | 0.40 ± 0.12 | ≤8.00 | 0.70 ± 0.10 | 100 | 8.3~15.0 |

| Φ18.0 | 19.0 ± 0.5 | 0.40 ± 0.15 | ≤9.00 | 0.80 ± 0.15 | 100 | 9.3~17.0 |

| Φ20.0 | 22.0 ± 0.5 | 0.40 ± 0.15 | ≤10.00 | 0.80 ± 0.15 | 100 | 10.4~19.0 |

| Φ22.0 | 24.0 ± 0.5 | 0.40 ± 0.15 | ≤11.00 | 0.80 ± 0.15 | 100 | 11.4~21.0 |

| Φ25.0 | 26.0 ± 0.5 | 0.50 ± 0.15 | ≤12.50 | 0.90 ± 0.15 | 50 | 12.8~24.0 |

| Φ28.0 | 29.0 ± 0.5 | 0.50 ± 0.15 | ≤14.00 | 0.90 ± 0.15 | 50 | 14.4~29.0 |

| Φ30.0 | 31.5 ± 1.0 | 0.50 ± 0.15 | ≤15.00 | 0.95 ± 0.15 | 50 | 16.0~29.0 |

| Φ35.0 | 36.5 ± 1.0 | 0.50 ± 0.15 | ≤17.50 | 1.00 ± 0.15 | 50 | 18.0~34.0 |

| Φ40.0 | 41.5 ± 1.0 | 0.55 ± 0.15 | ≤20.00 | 1.00 ± 0.15 | 50 | 21.0~39.0 |

Order Information

- Color: Black. other colors are available upon request.

- Nonstandard size: Special sizes are available upon request.

- Standard packaging: On spools, Cut pieces are available upon request.

- Ordering description: Specify product type, size (mm or inch) and color.